Researchers at Purdue University have found a way to fix a long-standing issue in manufacturing, where cutting a piece of metal can make its edges splinter or break apart.

They hope their solution will reap big savings in fuel and production costs.

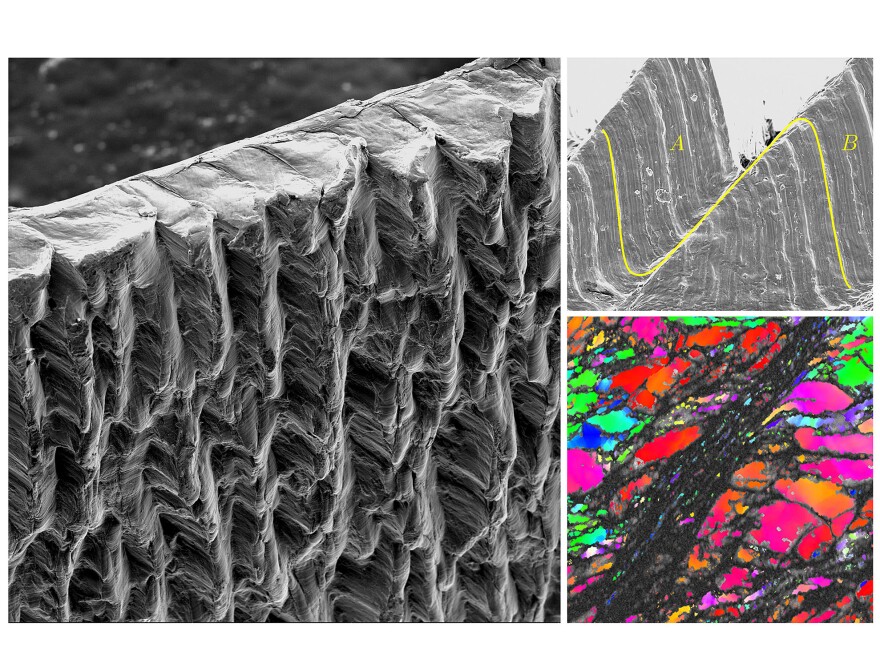

The problem is called a shear-band. It's a deformity that occurs when a cutting machine pushes through metal, scrunching up its edges at a microscopic level.

Industrial engineer Srinivasan Chandrasekar and his research partner, materials engineer Kevin Trumble, say the metal becomes almost molten in places and slides apart into tiny, jagged layers. This lowers the quality of the parts being made, and can even splinter them into pieces.

"We are constantly deforming metals, too, when we use them for applications – to produce shape, change, whatever, and to strengthen them," Chandrasekar says. "But beyond some point, these kinds of things can kick in."

Now, they say they have a way to control shear-bands, by adding a piece to the cutting machine at an angle to keep them from forming.

"It’s another tool element, and the material is sliding over the surface of that tool," Trumble says.

"Instead of one side being free," Chandrasekar says, the metal being cut "is now sandwiched between.”

This has special applications for the rolled-up sheets of metal, used in products such as cars. Right now, it takes a lot of time and space to flatten those sheets.

Chandrasekar and Trumble's new design creates a gap that metal can squeeze through, flattening it more quickly. They say this process could save up to 20 percent in production costs, and 40 percent in energy costs, over traditionally rolled sheetmetals.

The discovery could also help manufacturers work more effectively with lighter-weight metals, such as titanium and magnesium alloys.

They're increasingly in demand to make more fuel-efficient airplanes and cars, but they’re also more brittle – and thus more susceptible to shear-banding.

The research got about $2.5 million in funding from sources like the U.S. Department of Energy, the U.S. Army Research Office, Indiana and the National Science Foundation.

It's published in the September edition of the Proceedings of the Royal Society, the oldest peer-reviewed journal in the world.